| June 2010 |

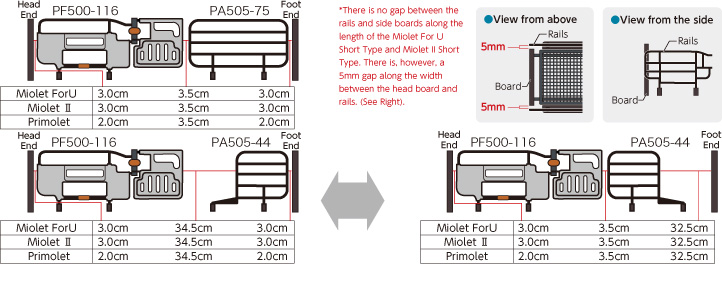

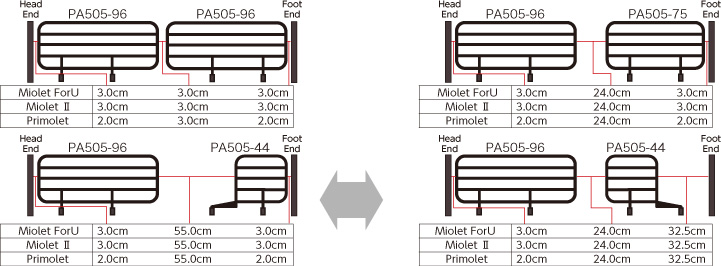

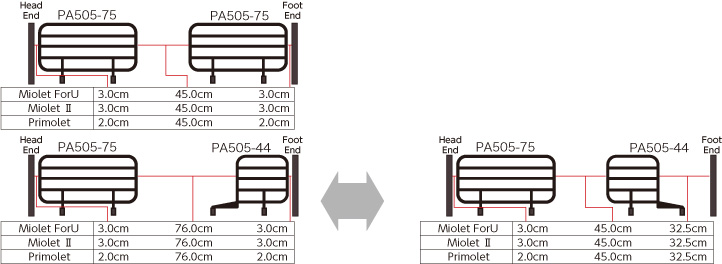

Rental Home Care Bed “Miolet” series, “Bed Grip PZR-116J”, and “Side Rail BG-96J, BG-75J, BG-53J” |

|---|---|

| November 2010 |

Auto Lock Bed Grip “Kneeparo” |

| December 2010 |

Independence Support Electric Bed “Primolet” |

| December 2011 |

Care Insurance Rental Nursing Care Bed “Miolet ForU” series and “PA500-FU44” Side Rail |

| August 2014 |

Care Insurance Rental Nursing Care Bed “MioletⅡ” |

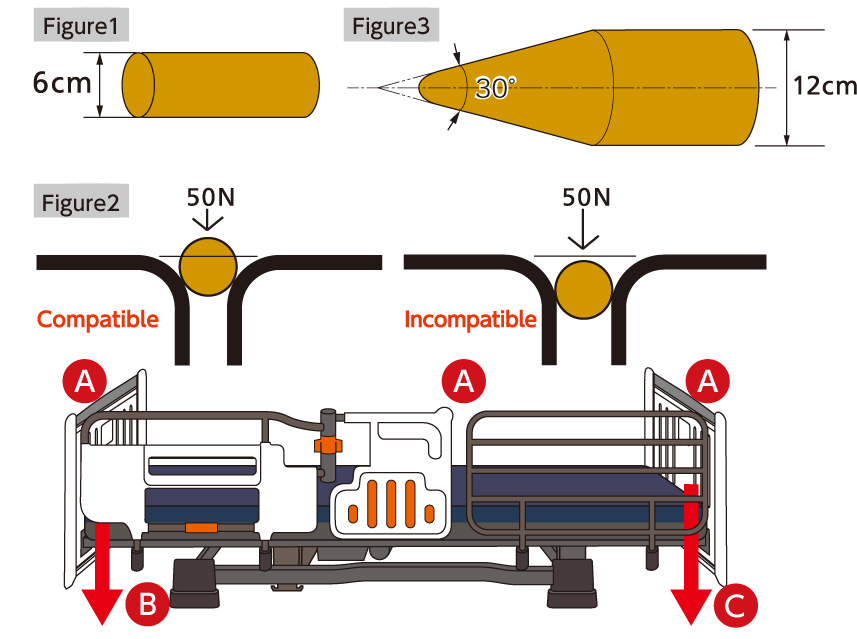

* Side rail and bed grip that are compatible with JIS certified beds (as of December 14th, 2011).

* Safety covers for the rails are available for each rail